Posted on: 15/05/2020, 01:00

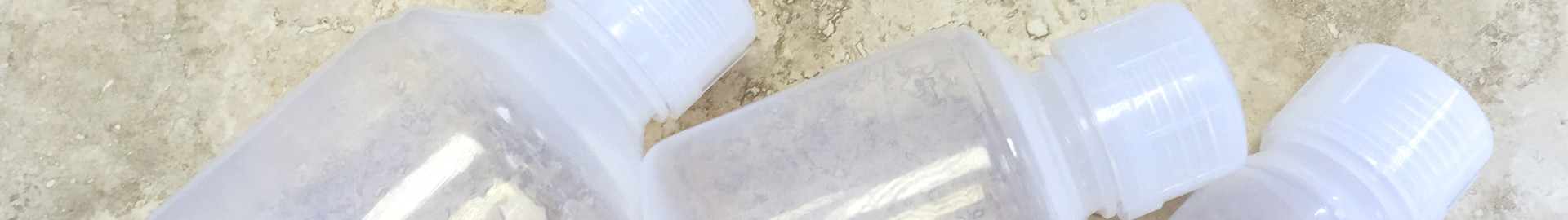

Flash Freezing with PFA Bottles

Flash freezing is the process of rapidly lowering the temperature of a liquid so that larger ice crystals do not have the chance to form. These larger crystals can potentially damage proteins and other critical components of the liquid. Flash freezing is a common process for freezing bulk drug substance (BDS) and can lead to failure of typical BDS containers.

Evidence from this study indicates that Savillex 1 L Purillex PFA bottles are suitable for dry heat sterilization at 250°C for 120 minutes and then flash freezing down to liquid nitrogen temperatures (-196°C) with no bottle collapse and no loss of bottle integrity. Several of the tested bottles passed integrity testing after exposure to a second flash freezing cycle. This is a testament to the structural durability of fluoropolymer materials when exposed to temperature extremes. It is also illustrative of the strength and reliability of the Purillex bottle seal technology.

Evidence from this test protocol indicates that Savillex 1 L Purillex PFA bottles are suitable for dry heat sterilization at 250°C for 120 minutes and then flash freezing down to liquid nitrogen temperatures (-196°C) with no bottle collapse and no loss of bottle integrity. Several of the tested bottles passed integrity testing after exposure to a second flash freezing cycle. This is a testament to the structural durability of fluoropolymer materials when exposed to temperature extremes. It is also illustrative of the strength and reliability of the Purillex bottle seal technology.